KunShan Systronics Automation Technology Co.,Ltd.

| parameter of machine | Power Supply | AC220V/AC380V 50HZ |

| Operating power | 1.0-3.0kw | |

| Working air pressure | 5.0-8.0kg | |

| Precision of screw | ±0.02mm | |

| Repeated positioning accuracy | ±0.01mm | |

| CCD accuracy | ±0.02mm | |

| CCD Correction accuracy | ±0.03mm | |

| Operating Mode | Touch Panel +PLC | |

| PC software system | Copyrighted software according customer requirement | |

| transmission interface | data reserved | |

| Size | 5000(L)*2500(W)*1500(H)mm | |

| Layout | Customize | |

| The Brand | Control system | Panasonic PLC |

| Drive system | Panasonic motor | |

| The transmission system | HIWIN/MISUMI | |

| Sensing system | Keyence, OMRON | |

| The CCD system | Basler | |

| Brand standard | Customize | |

| Successful cases | C/T = 16-20s/module, 16 points per module |

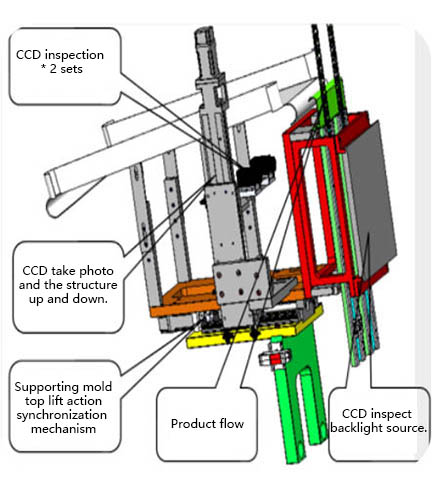

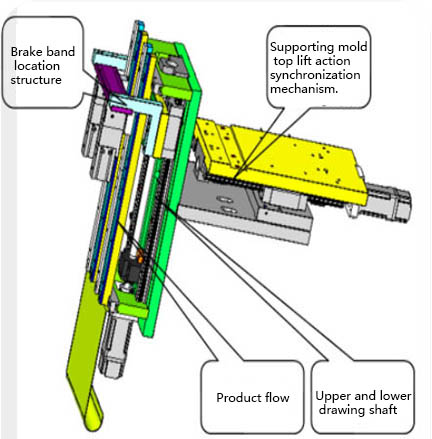

| Fuction of machine | Structure | Robot arm | |

| mold part | |||

| internal monitor | |||

| material striping | |||

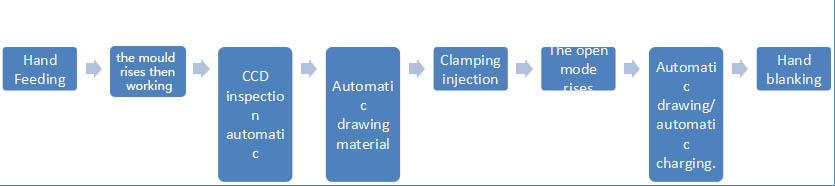

| Description | 1,material striping: this structure is to replace the worker to feed and blank the material, improve the injection 2,CCD inspection: first to check the product size to ensure the DUT yield, protection module. 3.3,Realize automatic continuous operation, improve production capacity, ensure good yield and stability, reduce manpower cost. 4. Reducing manpower and saving cost; | ||